In today’s world, the conversation around development is increasingly intertwined Sustainable Building with PEB. With climate concerns growing and resources becoming scarcer, industries worldwide are seeking greener alternatives. The construction sector, a significant consumer of resources and energy, is no exception. In a rapidly urbanizing city like Chennai, where new infrastructure is constantly emerging, the demand for construction that is both efficient and environmentally responsible is paramount.

This is where Pre-Engineered Buildings (PEBs) step in, offering a surprisingly robust and versatile solution for sustainable construction. Far from being just a fast and cost-effective option, PEBs inherently possess characteristics that align perfectly with eco-friendly building practices.

Why Pre Engineered Building is a Green Building Champion

Let’s break down how PEBs contribute to a more sustainable future:

1. Resource Efficiency & Reduced Waste: Traditional construction often leads to significant material waste on-site – think excess concrete, cut-off rebar, and discarded bricks. PEBs, however, are a different story:

- Reduced On-Site Waste: Because components arrive pre-cut and pre-drilled, there’s minimal cutting, welding, and modification needed on the construction site, leading to significantly less debris and landfill waste.

- Precision Manufacturing: Components are designed and fabricated off-site in controlled factory environments. This precision significantly minimizes waste generation at the source.

- Optimized Material Use: Engineering software ensures that every piece of steel is optimized for its exact load and function, reducing unnecessary material consumption.

2. The Power of Steel: Recyclability & Durability: Steel, the primary material in PEBs, is one of the most recycled materials globally.

- High Recycled Content: Much of the steel used in new construction, including PEBs, often contains a high percentage of recycled material, reducing the demand for virgin resources.

- 100% Recyclable: At the end of a PEB’s long lifespan (which can span decades), the steel components can be fully recycled without loss of quality or strength. This contributes to a circular economy, minimizing waste and resource depletion.

- Exceptional Durability: Steel’s inherent strength, coupled with anti-corrosion treatments, means PEBs are built to last, reducing the need for frequent repairs or premature demolition and rebuilding – further saving resources over time.

3. Energy Efficiency from Design to Operation: A sustainable building isn’t just about how it’s built, but how it performs throughout its life. PEBs offer multiple avenues for energy savings:

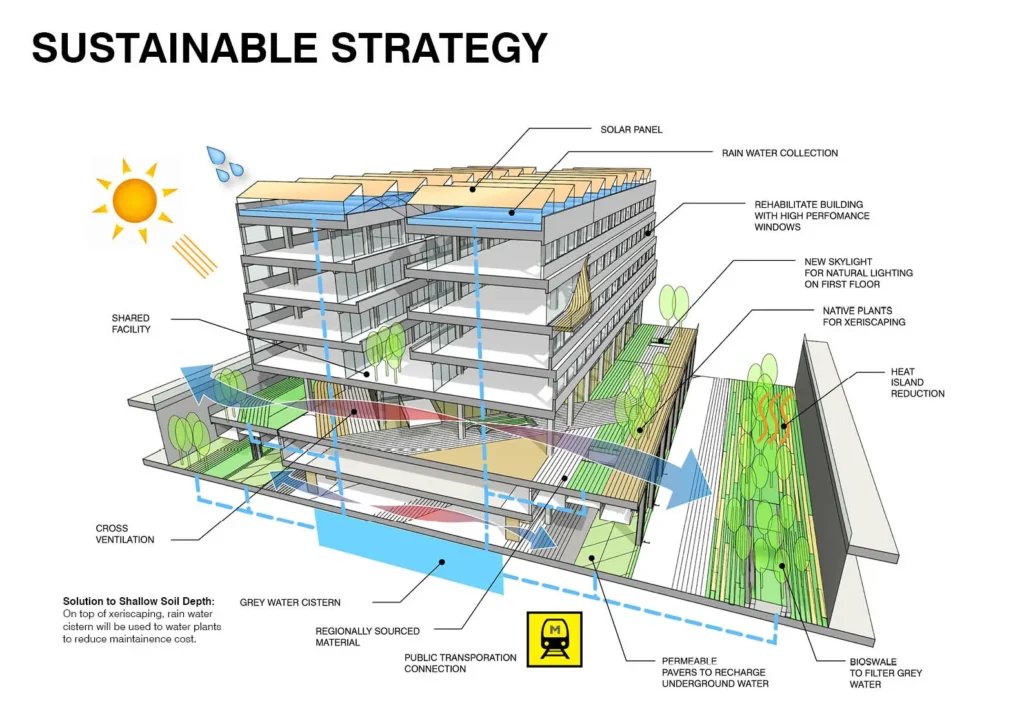

- Enhanced Insulation: PEBs are easily integrated with high-performance insulation materials (like insulated sandwich panels) for roofs and walls. This significantly reduces heat gain in Chennai’s hot climate and heat loss in colder regions, leading to lower HVAC (heating, ventilation, and air conditioning) loads.

- Natural Lighting & Ventilation: PEB designs can incorporate ample skylights, wall lights, and strategically placed vents, maximizing natural daylight and promoting cross-ventilation, thereby reducing reliance on artificial lighting and air conditioning.

- Reflective Roofing: Specific roofing materials can be used to reflect solar radiation, further reducing the cooling load on the building.

- Renewable Energy Integration: The robust and adaptable structure of PEBs makes them ideal for integrating renewable energy systems, such as rooftop solar panels, directly contributing to net-zero energy goals.

4. Reduced Environmental Impact During Construction: The construction phase itself can have a significant environmental footprint. PEBs minimize this:

- Faster Erection: Due to pre-fabrication, PEBs are erected much faster than traditional buildings. This means a shorter period of on-site activity, reduced noise pollution, and less disruption to the local environment and community.

- Lower Emissions: Less on-site construction time translates to less fuel consumption by heavy machinery and fewer vehicle movements, leading to a reduction in carbon emissions associated with the build process.

- Less Water Consumption: PEB construction uses significantly less water compared to traditional wet construction methods (e.g., concrete curing), a crucial advantage in water-stressed regions like many parts of India, including Chennai.

5. Adaptability, Deconstruction & Reduced Carbon Footprint:

- Flexible & Expandable: As businesses evolve, their space needs change. PEBs are inherently designed for easy expansion, modification, or even deconstruction and relocation. This adaptability extends the building’s utility and prevents the need for new construction, conserving resources.

- Lower Embodied Carbon: The combination of optimized material use, high recyclability, and efficient manufacturing processes means PEBs generally have a lower “embodied carbon” footprint (the CO2 emitted during material production and construction) compared to conventionally built structures.

PEB and Green Building Certifications in India

For businesses in Chennai looking to demonstrate their commitment to sustainability, PEBs can significantly contribute towards achieving green building certifications like:

- IGBC (Indian Green Building Council): Another prominent certification body in India, with various rating systems where PEB features contribute positively.

- LEED (Leadership in Energy and Environmental Design): A globally recognized certification for green buildings, where PEB’s energy efficiency, material choices, and waste reduction can earn significant points.

- GRIHA (Green Rating for Integrated Habitat Assessment): India’s own national rating system for green buildings. PEBs can score well in categories like energy performance, material selection, and construction management.

Investing in a Sustainable Future with PEB

As Chennai continues its growth trajectory, the emphasis on sustainable development will only intensify. Choosing a Pre-Engineered Building for your next warehouse, factory, commercial space, or institutional facility is not just a smart business decision for speed and cost-effectiveness; it’s a conscious step towards environmental responsibility.

By embracing PEB, you’re investing in a building that is resource-efficient, minimizes waste, conserves energy, and stands as a testament to modern, eco-friendly construction. It’s a choice that benefits your bottom line, enhances your brand image, and contributes positively to the planet.