What is Prefabricated Construction (Prefabrication)?

Prefabricated construction, often referred to as prefabrication, is all about creating building components in a controlled environment away from the construction site. Once these parts are ready, they’re brought to the site for assembly.

Brief History and Evolution

Let’s take a quick look at the history and evolution of this fascinating topic.

- It all started way back in ancient times with things like timber trackways and Roman military camps.

- During the world wars, it really gained traction and became more popular.

- Today, it’s evolving even further with the rise of smart technology and green building initiatives.

Why It’s Gaining Popularity Globally

- Projects are getting completed faster than ever.

- A noticeable boost in quality control.

- Cost-effective and sustainable.

- It helps reduce on-site labor and minimizes risk.

What is Prefabricated Construction?

Prefab construction makes the building process a lot smoother by creating components such as walls, slabs, and even whole modules right in a factory. This approach not only boosts consistency but also speeds things up significantly.

Difference Between Traditional and Prefabricated Construction

| Aspect | Traditional Construction | Prefabricated Construction |

| Location | Built On-Site | Built off-site (factory) |

| Time | Longer | Shorter |

| Quality Control | Variable | Controlled |

| Environmental Impact | Higer | Lower |

| Labor Requirements | More on-site labor | Less on-site labor |

Prefabrication Construction Techniques

- Panelized Systems : Flat panels (walls, floors, roofs) prefabricated and assembled on-site.

- Modular Construction: Entire rooms or building sections pre-built and installed like blocks.

- Precast Concrete Systems: Concrete parts cast in reusable molds and transported to the site.

- 3D Volumetric Construction: Fully enclosed modules created off-site and joined to form the final structure.

- Hybrid Systems: Combination of two or more techniques to optimize design and performance.

Examples of Prefabricated Construction

Residential Housing

- Modular villas

- Apartment blocks

Commercial Buildings

- Prefab office complexes

- Retail units

Healthcare and Educational Facilities

- Hospitals built rapidly during emergencies (e.g., COVID-19)

- Prefab classrooms and training centers.

Emergency Shelters

- Disaster relief shelters

- Military housing units

Prefabricated Construction in India

Growth in Indian Real Estate and Infrastructure

Driven by urban housing demand, smart cities, and fast-track projects.

Government Initiatives

- Pradhan Mantri Awas Yojana (PMAY)

- Support for green and affordable housing

Key Players in the Indian Market

- BG Shirke Construction Technology

- Tata Steel Nest-In

- Champion Prefabs

- NTPC’s Ash-Based Eco-Homes

Case Studies

- Technopark’s prefab office (Kerala)

- NTPC’s eco-house (Chhattisgarh)

Advantages of Prefabrication

- Reduced Construction Time

- Cost-Efficiency

- Better Quality Control

- Lower Environmental Impact

- Improved Worker Safety

Disadvantages of Prefabrication

- High initial factory setup cost

- Limited design flexibility

- Transport and logistics complications

- Requires skilled assembly teams on-site

Future of Prefabricated Construction

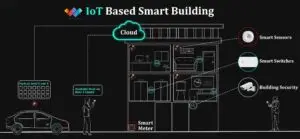

- Smart homes with IoT integration

- AI in design and scheduling

- Use of sustainable, recycled materials

- Global prefab market to grow at 5–8% CAGR

- India will expand prefab use in both urban and rural housing

Conclusion

Our building process is being transformed by prefabricated construction, which makes it quicker, more intelligent, and more environmentally friendly. Prefab is expected to become a key component of the future building landscape due to rising demand, advancements in technology, and government support, particularly in India.