A purlin is a horizontal beam or bar that provides structural support for buildings, typically beneath the roof. The rafters of the building or its walls support the purlins. Although they most frequently employed in metal buildings, these can also replace densely pack rafters in wood-frame constructions. The purlins of a roof sustain the weight of the roof Deck. The hardwood panel, ply board, or sheet metal that forms the roof surface is known as the roof deck. This often made of concrete, filled with some sort of weatherproofing, and frequently cover in insulation.

Purlins come in a variety of varieties and are categorise into groups based on the components they comprise of and how they are shape. It have a variety of applications, such as supporting a structural wall or floor. Purlins are crucial to the structure of the roof because without them, there would be no frame for the roof’s sheeting to rest on.

Defination of Purlin

The roof deck or sheathing loads carried by the purlins, which is support by substantial rafters, building walls, steel beams, etc. Purlins frequently used in pre-engineered metal construction systems, as well as both the traditional post-and-beam and more modern pole construction approaches for frame construction, as opposed to closely spaced rafters.

Steel Purlin:

Alternatives to traditional wood purlins include steel purlins. They are thin, consistent in size, precise, and easy to use. They considerably enlarge and shrink when temperatures are drastically different. Typically, cold-formed steel that is thin enough to pass through the screws is used to make steel purlins.

Thin steel sheets rolled or pressed into place to provide cold-formed steel the correct shape. It is easier to work with for the maker and less expensive than hot-rolled steel. Despite being stronger under stress than hot-formed steel, cold-formed steel is more likely to split than bend.

Various metals used to make purlins. Some are straightforward mild steel with average strength, while others have varied GSMs of zinc coating. When the weather is harsh, a special coating to be added on top of the zinc coating.

Types of Cold Formed Purlins:

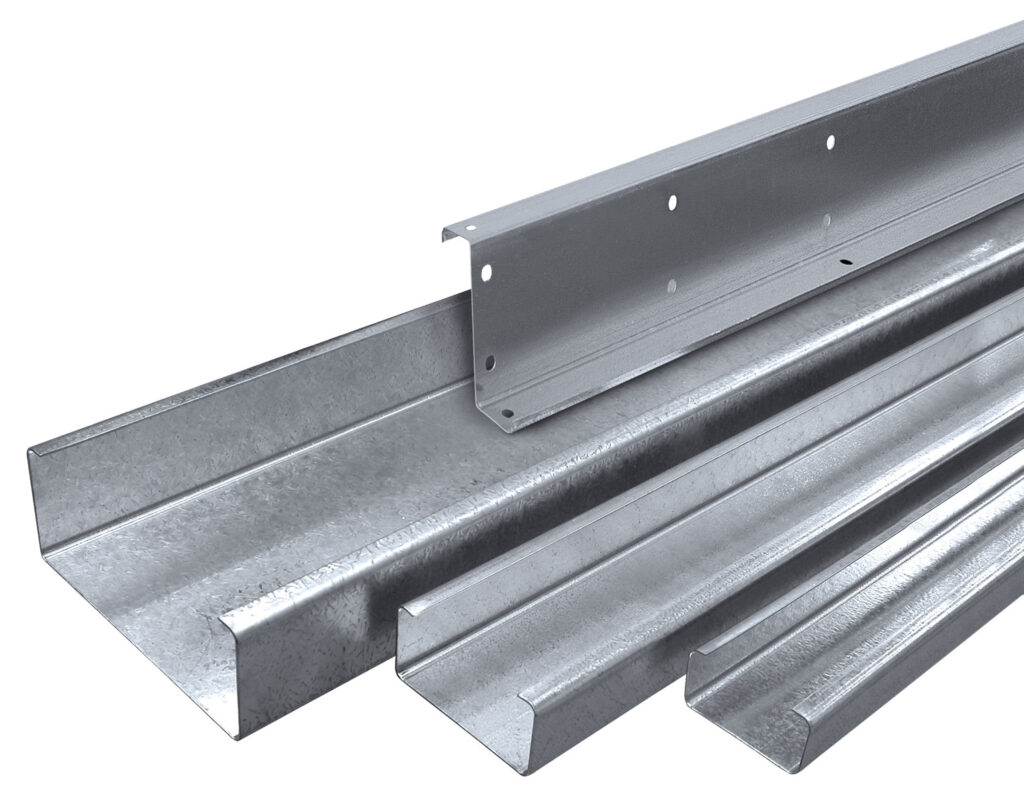

C Shaped Purlins:

As their name suggests, C purlins formed like the letters of the C alphabet and typically used to support walls and floors. C section or cee section purlins constructed to form the walls and floor joists of a building shell structure, making them ideal for holding the beams needed for flooring. These may also make use of our C segment purlins for door mounting, parapet rails, window trimming, and roof trimming.

Z Shaped Purlin:

Stronger than C purlin, a different type of Z purlin is typically utilises at joints and overlaps. Z purlins, also known as zed purlins, horizontal beams used to shape the roof and wall joists of building shell structures. They serve as sheet supports to hold the roofing firmly fastened and securely in place. As they positioned in between the roofing sheets and the building. Z purlins employed most frequently in agricultural and industrial structures. Because of their relatively high flexibility and lightweight characteristics. Which make them highly adaptable for use in a variety of different sizes.

C Shaped SIGMA Purlins:

“SIGMA” purlins C-shaped with unique ribs (Bends in web).

These purlin kinds outperform the previous two types of purlins due to their superior structural qualities. Sigma section purlins constructed to form the walls and floor joists of a building shell structure. Making them useful for supporting the flooring beams as well. These may also make use of our C segment purlins for door mounting, parapet rails, window trimming, and roof trimming.

Why Purlins Considered Reliable Building Materials?

You can see apartments, industries, warehouses, and tall skyscrapers that practically reach the sky everywhere you walk. People now rely on this concrete jungle to provide them with a suitable location for rest, business, dining, and other activities. What to be understood is how these high-rise structures. In addition to the hectares of warehouses, constructed utilising extremely durable materials.

The very thing that makes it appear so magnificent to create factories and other facilities to survive longer efficiently is the range of construction materials that are readily available on the market. One of the many different architectural materials that may be utilised effectively to aid and support roof deck or sheathing is purlin.